| Payment Type: | L/C,T/T,D/P,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Min. Order: | 100 Piece/Pieces |

| Delivery Time: | 3-7 Days |

Basic Info

Model No.: M7 M7X1

Material: Stainless Steel

Type: Common

Usage: Machinery

Rotation Direction: Left Rotation

Certification: ISO, GS

Customized: Customized

Size: M2 M6 M7 M8 M12 Etc

Materials: Stainless Steel, Stainless Steel, Brass

Circles: 6, 8, 16 Or As Your Request

Additional Info

Packaging: carton or plywood box

Productivity: 10000 pcs/week

Brand: xinmingde

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 10000000/month

Certificate: ISO9001

HS Code: 7318160000

Port: Qingdao,Shanghai,Guangzhou

Product Description

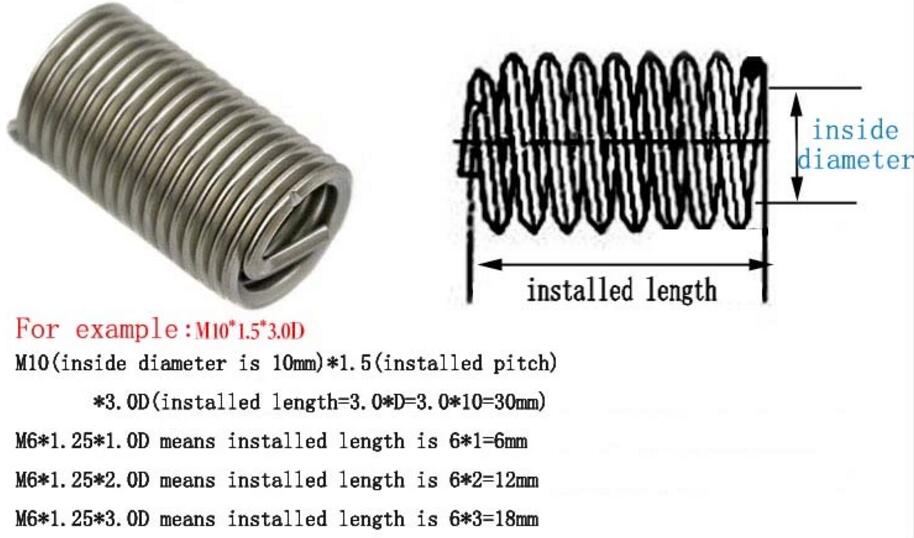

M7 M7x1 stainless steel/ copper wire thread insert

Wire thread insert greatly extend the service life of the matrix, they can disperse stress to protect matrix thread,

made of cold rolled diamond stainless steel wire with high strength, high precision and smooth surface

Wire embedding a screw aluminum, magnesium, iron, glass, plastic and other low strength of screw thread hole of engineering materials, can form in line with international standards of high-precision internal thread, has high bonding strength, the function of the earthquake, impact resistance and wear resistance.

| Material | Copper, Brass, Phosphor bronze, Beryllium Copper, Aluminum, Stainless steel, Carbon steel, Iron, Alloy steel, Tool steel, Tungsten carbide, HSS, Titanium, Ductile iron, etc. |

| Surface treatment | Electro-polishing, Electroless nickel plating, Silver plating, Golden plating, Zinc plating, TIN plating, Chrome plating, Bead Blasting, Phosphating, Turning, Heat treatment, Carburization, Case hardening, Sand blasting, Passivate, Black Anodize, Vacuum heat treatment, Super/low temperature treatment, steel oxidizing dark-blue etc. |

| Equipment | Machining center, CNC, Lathe, Turning machine, Milling machine, Drilling machine, Internal and external grinding machine, Cylindrical grinding machine, Tapping drilling machine, Wire cutting machine, CNC high-speed engraving machine etc. |

| Heat Treatment Capability | Annealing, normalizing, tempering, nitriding, carbonitriding, carburizing and induction hardening |

| Precision Machining Capability | 1) Machine's rotating speed: 5000rpm - 30000rpm |

| 2) Machining precision tolerance: 0.005 - 0.01mm | |

| 3) Roughness value: < Ra 0.2 | |

| 4) Minimum cutting tool: 0.1mm | |

| 10 sets of precision latch machines can help us to do the diameter smaller than 20mm(0.78inch) parts | |

| Inspection Machines | CMM, projector, universal testing machine, surface gauge and screw gauge |

| Application |

Car parts, Medical devices, optical parts, Electric sheets, Industrial, Medical, Power / Energy, Audio, etc.

|

Features:

1. Increasing the bearing capacity and fatigue resistant of the insert connecting part.

2. Saving material,improving the working

3. Abrasion resistant;Corrosion resistant;Heat-stable.

4. Easy to repair the internal thread and assemble.

5. Excellent material quality--Material: Stainless steel, super alloy.

Installed Length=Inside Diameter*XD

Stainless steel wire thread insert / Tangless Coilthread

Related products

M4 Thread Insert

M8 Thread Insert

M3 Thread Insert

Wire Thread Inserts

Testing Equipment

welcome your inquiry...

Contact Person: Na Lou

Phone:86-0373-5063186

Fax:

Address: BI1-2, Pioneer Park, No. 2, High-Tech Zone,Xinxiang,Henan

Sweep wechat

© 2019 CHINA WAY. All Rights Reserved. Xinxiang Xin Ming De Machinery Co., Ltd., Inc. All rights reserved. site map. sitemap.html